I am building a homebuilt airplane called a Sonex. I have been working extremely hard to finance this project since August 2016. In April 2017, I purchased a partially completed Sonex. In February of 2018 I bought a Aerovee 80hp engine. I will still need to buy avionics and am such, working a million odd jobs to earn enough money.

What is a Sonex?

Well first we have to ask, are you talking about Sonex the company, or the Sonex Airplane?

Sonex is an aviation company, based out of wisconsin, that produces airplane kits for builders to make at home. A kit from Sonex includes the plans for making every single part in the plane and how they fit together, most of the hardware you will need (nuts screws bolts) , and a great deal of the material needed. With a kit, you can build realistically build a Sonex airplane in under 2 years in your garage. You are then left needing to buy certain customization items, instrument's, upholstery, and your choice of an engine.

The Sonex-A is a 2 seat, pilot and 1 passenger, small airplane. It is capable of performing aerobatics and has very responsive controls, akin to a fighter plane, or a sports car. Depending on what engine you instal its cruise speed is between 120 mph and 140mph, and it burns 5-8 gallons of fuel and hour in cruise flight.

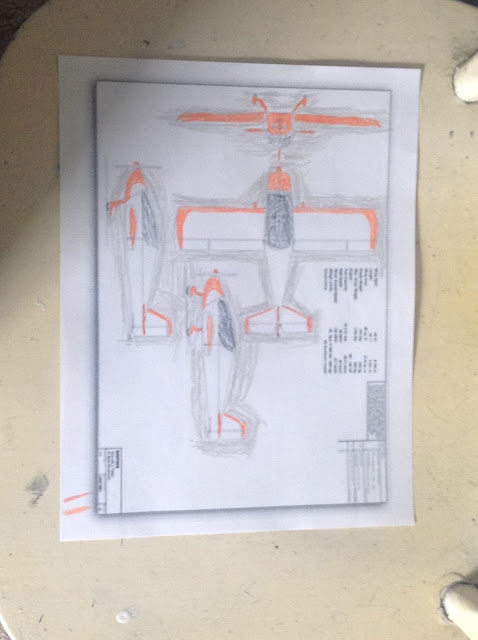

For my Sonex (kit#1612) after a long period of sketching different ideas I have tenatively decided to vynll wrap my pane when it's done, this is my proposed color scheme.